MONOLITHIC FORMWORK SYSTEM

PDL has introduced a revolutionary formwork building system for forming cast-in-place reinforced concrete structures.

Using our overall formwork solution, it can cast all building components in one operation, including:

- wall

- Floor

- Cylinders and beams

- stairs

Door and window opening included. The last structure is an extremely strong strength and high dimensional accuracy and only requires a minimum of final surface finishing “degreaser coating” to achieve high-quality surface finishing.

Our overall formwork can significantly increase the construction speed, with an average construction period of 7-8 days per layer

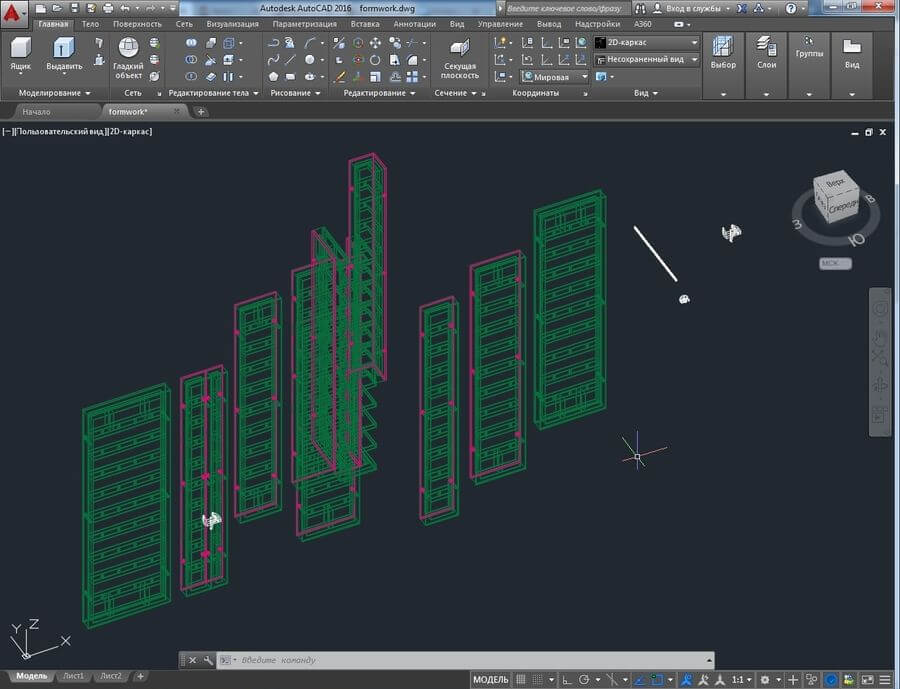

Flat Tie Type Panel System.

The Flat type panel system is a new integrated forming and shoring system.

The panels are reinforced flat tie, pin & wedge, which can make sure good flatness of the wall.

Flat Tie Type Panel System.

Flat type panel system a new integrated forming and shoring system.

The panels are reinforced flat tie, pin & wedge, which can make sure good flatness of the walls.

The aluminum panel system is a new integrated formwork and support system.

Tie Rod Type Panel System.

The aluminum panel system is a new integrated formwork and support system.

Firstly, It is a flexible solution for monolithic casting or two-stage casting of wall, beam, slab and staircase.

Secondly, The panels are reinforced with a tie rod and a wing nut, which can ensure good verticality of the walls.

Thirdly, The smooth finish of the concrete after removing the formwork eliminates the need for costly plastering.

To simplify, Inimitable premium quality products are the reason why PDL pioneered the aluminum formwork industry in Pakistan. One of the fundamental principles of PDL Aluform’s existence has never, to compromise quality for short-term profits. PDL has a dedicated team of designers, engineers and workers who strive to consistently provide the highest quality products.

- Grade 6061 T6 aluminum used in all panels

- One-piece moldings with a width of 600 mm

- The panels weigh 20.5 (+/-0.5) kg/m2

- Panel thickness between 3.7 mm – 4 mm